How Do Solar Panels Work? (3 Tips to Pick Quality Panels for Your Projects)Posted by Stephen Shickadance in How Solar Lights Work.

In order to understand how a solar panel works, it’s important to know what a panel is made from. When discussing photovoltaics (another word for solar panels), the vast majority of panels are made from silicon.

It’s one of the most abundant substances available for use. Silicon dioxide goes through several different processes before it’s manufactured into usable silicon. Also, it’s been used in technology for several decades, so it’s a well-understood material. How is a Solar Panel Made?After silicon is gathered, it’s heated inside of a large vat. A silicon “seed” is dipped into the molten silicon and is slowly drawn out. The result is a silicon ingot, a cylinder of 99.9% pure silicon. This is called the Czochralski process. Very thin wafers of silicon are cut from the ingot and then carried off to where they go through the doping process which establishes what’s called the p/n junction, a very important step in the process of converting light into usable energy. How Do Solar Cells Work?

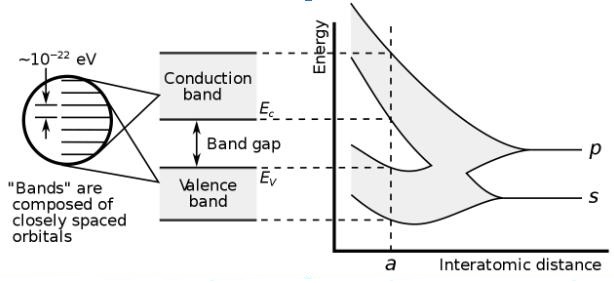

The p/n junction is the “magic process” for solar panels. Solar cells operate with what’s known as the bandgap, which is a difference in energy between two atomic energy bands known as the conduction band and the valence band. The gap size, measured in electron volts, determines the conductivity of the material. At 3eV, the material in question functions as a fantastic insulator since electrons do not have enough energy to jump the bandgap. If there is no band gap, meaning the conduction and valence bands overlap, the material works as a fantastic conductor. Silicon is a semiconductor, so it falls somewhere in the middle. The bandgap measurement for silicon is 1.11 eV, so valence electrons, given enough energy, can pass through the bandgap with the help of photons, or units of light. When photons strike silicon, free electrons jump from the valence band to the conduction band where they are transferred to DC power. Kinds of Solar CellsCurrently, the best solar cells are manufactured from monocrystalline silicon. There are many other technologies that are used in solar cell manufacturing. But why this specific kind? Here are a few other technologies used in solar cell production that don’t make the cut.

The reason why mono-Si solar cells are still the best choice on the market is because of their long lifespan (25 years), high efficiency (25% maximum in lab results), and suitable panel sizing for commercial projects. Solar cells that need large array sizes don’t work well simply because the panels are too large for proper wind resistance. Silicon is a well-researched substance for electronics since it’s used in microprocessor production. Also, it’s comparatively less toxic than Cadmium or Indium.

CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=314282 3 Tips to Pick Quality Solar Panel from the ManufacturerIf you don’t have quality panels, you’ll lose significant ROI on your projects. Low-quality panels degrade over time for different reasons:

Here are 3 things to do and look for when browsing manufacturers for the right type of solar light.

Adhering to these guidelines will ensure that the manufacturer and their products will deliver the best return on investment and last a long time. Greenshine New Energy is a solar lighting company that develops and manufactures industry-leading solar-powered lighting systems. We utilize monocrystalline silicon to provide the highest efficiency on our solar panels. Solar lighting is a cost-effective solution for commercial, residential, and industrial projects. Contact our engineers today to find out more about solar panels you can use for your projects.

How Solar Lights Work

|

ArchivesNo Archives Categories

Want More Info? |

LATEST NEWS & ARTICLES